Based on our years of working in the different sewn products industries, we know what a well-run factory floor looks like, and we know how to help you achieve quick results to reduce costs and improve profitability.

We partnered with shop floor control vendor, IPE. You can start small and focus on solving your problems around motivating employees and driving the behavior you want on the shop floor by focusing on incentive payroll.

But if you know you are ready for more and ready to transform and achieve shop floor optimization - then we can help with that too.

One of the things we looked for in our partnerships was a platform that allows our clients to start where they are - a low barrier to getting started on changing the shop floor. We also wanted a partner that has the breadth of experience and product offering to handle all your shop floor control needs. And we found that in IPE.

IPE was formed in 2010 to fill the gap in incentive payroll and shop floor control solutions for manufacturers in the sewn products industries. IPE principals have over a century of combined experience with incentive payroll solutions for apparel and sewn products manufacturers.

IPE Solutions

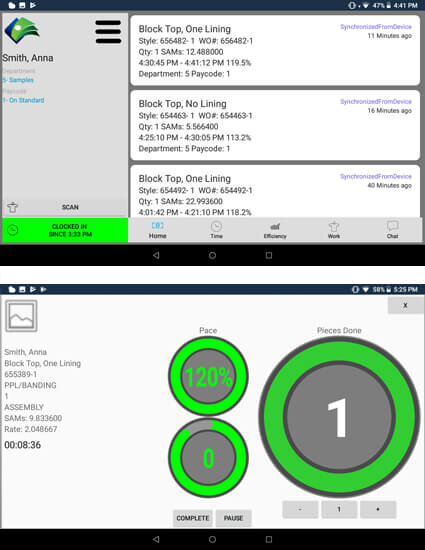

IP Realtime™ utilizes wireless networking and off-the-shelf tablet technology to collect and report all production activities immediately as they occur throughout the shift. This always-on data collection and reporting eliminates ticket printing and gum sheets to provide immediate feedback to workers and managers on individual, team and overall plant performance.

IP Realtime helps employees and teams pace themselves to increase earnings by providing on-demand performance feedback.

It also empowers supervisors and managers to quickly track order status, monitor individual and team productivity, resolve quality issues, manage off-standard events, and better balance production lines.

IP RealTime - Shop Floor Control

How IP Realtime Works:

IPE has changed the game with IP RealTime incentive payroll and shop floor control solution.

This simple and affordable to deploy and use solution streamlines incentive and hourly payroll tasks, while giving you and your teams better tools to manage the day to day operation of all your production activities.

From issuance of the production order, to production data collection and gross payroll processing, IP Realtime streamlines plant-wide processes.

Data collection is managed through standard WiFi and off-the-shelf Android® devices to keep it simple and affordable.

By capturing all production data instantly as it occurs, IP RealTime empowers supervisors and managers to quickly track order status, monitor individual and team productivity, resolve quality issues, manage off-standard events, and better balance production lines.

IP-Batch enables daily processing & reporting for apparel and sewn products manufacturers to manage and simplify piecework payroll calculation and shop floor control.

IP Batch™ is a simple-to-use incentive software solution for daily or weekly calculation of production information and employee gross incentive pay using traditional bundle tickets and production sheets. Key capabilities include quick data input via handheld scanner, bar-coded bundle ticket printing, source to gross payroll calculations, time & attendance, shop floor control, quality control, care label printing, management reporting, and other optional modules designed specifically for sewn products and soft goods producers.

IP Batch - Incentive Payroll

How IP-Batch Works:

The Microsoft®.NET® based solution helps manage operations, styles and cut orders. The printing of bar-coded bundle tickets, submitted on gum sheets makes data collection easy via a USB hand-held scanner.

Pay Codes are defined to calculate both on standard and off standard pay, as well as make-up (daily or weekly), overtime premium, small bundle premium and shift differential pay.

Each of these gross pay types can then be consolidated and transferred to a gross-to-net payroll system (ADP, PayChex, Performance Payroll or .csv file). Labor cost reports by department, cost center, or plant show where excess costs exist in the manufacturing operation. The system can also be set-up to manage a single sewing plant or configured for central cutting/remote sewing.

IP-Batch can be integrated with 3rd party ERP systems to eliminate double entry of data. ERP production orders can be sent to IP, and production order (cut) completed quantities can be directed back to the ERP system on a daily basis. IP also integrates with Eton and GerberMover unit production and other production systems.

When you are ready to see the IPE software in action, book your demo with TexTempo today!